A deck is a great place to enjoy the outdoors at your home. It can also improve the value of your home, as well. If this is something you have thought about doing but figured it was too much of a task to do by yourself, I'd like you to think again. Sure, decks can be of many different sizes, styles, and can definitely require different skill levels. If you follow some simple guidelines and suggestions, building a deck can be an enjoyable experience and definitely be a DIY project for you!

Before you get started, here are a few things to keep in mind:

- When deciding the dimensions of your deck, think about the lumber you'll need. Lumber is usually sold in 2 foot increments (8', 10', 12', 14', 16', & 20'). Keeping the deck as close to these dimensions will help the overall cost of materials. Also, the length of you floor joists will determine was size boards you will have to use. For example, with joists spaced at 16", a 2"x 8" can span up to 12'. A 2"x 10" can span up to 15' and a 2"x 12" can span up to 18'. This can definitely affect the cost of materials as well.

- How high will the deck be off the ground? The higher your deck is off the ground means you'll need longer posts and more steps to build. The lower your deck is to the ground means you can get by with shorter posts and less steps. If you build the deck close to the ground, you may not even need rails.

- What materials do you want to use? The most common used material is treated pine, which is also the most economical. With a little more cost, you could go with cedar. Cedar looks good and is naturally resistant to rot. The latest product on the market for decks is Composite Decking material. This is a great product because there are no splinters and it never rots or needs to be painted. The downside of it is the cost. Composite deck material is very expensive, but over time, can save you money because of it doesn't need to be treated periodically and because of its overall longevity.

Tools Needed:

- Hammer

- Framing Square

- Tape Measure

- Level

- Circular Saw

- Drill

- Posthole Digger

- Ratchet or Wrench

Materials Needed:

- Deck Lumber

- Joist Hangers

- Concrete (Quickrete)

- Screws

**Affiliate links are used on this page. See my disclosure page for more info on affiliate programs.

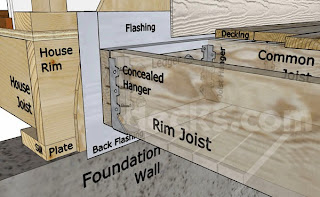

The most important components of a deck are the posts, beams, ledgers, and joists. These parts support and distribute the weight. (See Picture Below)

The most important components of a deck are the posts, beams, ledgers, and joists. These parts support and distribute the weight. (See Picture Below)

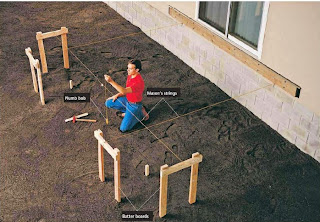

To get started, decide on where the deck is going to be located and attach the ledger board (2"x 8") to the house. This should be attached using lag bolts and they need to be long enough to reach the rim joist on the house and/or the studs of the house. Make sure to attach a piece of metal flashing between the ledger board and the house, with the flashing extending behind the house siding where it is above the deck. The ledger will serve as a reference for laying out the concrete footings that are needed for the posts. A good practice for this is using batter boards and string (See picture).

While doing this, you should check to make sure your layout is square. The best way to do this is to measure from one corner to the opposite corner diagonally. After this, repeat the process for the opposite diagonal corners. Make adjustments if needed to ensure the two measurements are equal. Once the two measurements are the same, the layout will be square.

At the corners of the layout, you will need to dig a hole for concrete footings. These footings will help support the weight of the deck coming down from the deck posts. They will also need to be deep enough to be below the frost line so

that the deck doesn't move when the ground freezes during the winter. Frost lines vary depending on the region you live in so make sure you check with your local building codes to determine this depth. You should have footings for posts on every corner, as well in between the corners, not to exceed 5' between them.

Once the footings are poured and have dried, you can now attach a metal post bracket to the concrete. This will need to be in the right place so that the post will fit in the corner perfectly. After all brackets are in place, cut the deck posts (support legs) long enough to reach just above handrail height. Now install all posts in the brackets. You should make sure they are plumb and hold them in place (vertically level) with 2"x 4" braces going to the ground.

Now that the ledger board is up and the posts are standing and braced off, attach the rim joists (boards going around the perimeter of the deck) to the posts and ledger using 3" exterior screws. These will also be 2"x 8" boards. A 4' level will help to ensure that they are level all the way around. Once the rim joists are in place, start measuring your layout along the ledger board and the outer rim joist (the board at the opposite end from the ledger). This layout will show you where the floor joists will be placed. All floor joists should be, at minimum, 16" on center. This means that, from the center of one joist to the center of the next, there will be 16". Spanning the joists further than this will allow the deck planks on the floor to sag and bounce. 2"x 8" joist hangers should also be used on the inside edge of the ledger and rim joists to allow for the floor joists to lay in and fasten to.

Once all of the 2"x 8" floor joists have been installed, you will now need to install bridging (sometimes called noggin) between the joists. This is to strengthen the frame and is usually done by using up all the scrap material and cut-offs. These will be boards placed between the joists and should not exceed 8' between them. You are now ready to start installing the flooring.

Flooring can be done using either 2"x 4"s, 2"x 6"s, or treated deck planks (these are typically 1"x 5.5"). These planks can be installed either perpendicular to the joists or at an angle. The most common way is perpendicular. It is a good idea to start the flooring along the outside edge of the deck. All planks need to extend past the rim joists by at least 1" to 1.5". Make sure you leave a 1/4" gap between these planks to allow for water to drain. You will also need to use a Jig saw to cut a notch around the posts. By starting at the outer edge, usually the notch around the post will be done with the first two rows. Attach the planks with 3 exterior screws at each floor joist. When you get to the last row, you will need to rip the board down to the size needed to fit next the the house wall.

Please look the for the next post How to Build a Deck- (Rails) where we will discuss different types of handrail systems and how to install them!

While doing this, you should check to make sure your layout is square. The best way to do this is to measure from one corner to the opposite corner diagonally. After this, repeat the process for the opposite diagonal corners. Make adjustments if needed to ensure the two measurements are equal. Once the two measurements are the same, the layout will be square.

At the corners of the layout, you will need to dig a hole for concrete footings. These footings will help support the weight of the deck coming down from the deck posts. They will also need to be deep enough to be below the frost line so

that the deck doesn't move when the ground freezes during the winter. Frost lines vary depending on the region you live in so make sure you check with your local building codes to determine this depth. You should have footings for posts on every corner, as well in between the corners, not to exceed 5' between them.

Once the footings are poured and have dried, you can now attach a metal post bracket to the concrete. This will need to be in the right place so that the post will fit in the corner perfectly. After all brackets are in place, cut the deck posts (support legs) long enough to reach just above handrail height. Now install all posts in the brackets. You should make sure they are plumb and hold them in place (vertically level) with 2"x 4" braces going to the ground.

Now that the ledger board is up and the posts are standing and braced off, attach the rim joists (boards going around the perimeter of the deck) to the posts and ledger using 3" exterior screws. These will also be 2"x 8" boards. A 4' level will help to ensure that they are level all the way around. Once the rim joists are in place, start measuring your layout along the ledger board and the outer rim joist (the board at the opposite end from the ledger). This layout will show you where the floor joists will be placed. All floor joists should be, at minimum, 16" on center. This means that, from the center of one joist to the center of the next, there will be 16". Spanning the joists further than this will allow the deck planks on the floor to sag and bounce. 2"x 8" joist hangers should also be used on the inside edge of the ledger and rim joists to allow for the floor joists to lay in and fasten to.

Once all of the 2"x 8" floor joists have been installed, you will now need to install bridging (sometimes called noggin) between the joists. This is to strengthen the frame and is usually done by using up all the scrap material and cut-offs. These will be boards placed between the joists and should not exceed 8' between them. You are now ready to start installing the flooring.

Flooring can be done using either 2"x 4"s, 2"x 6"s, or treated deck planks (these are typically 1"x 5.5"). These planks can be installed either perpendicular to the joists or at an angle. The most common way is perpendicular. It is a good idea to start the flooring along the outside edge of the deck. All planks need to extend past the rim joists by at least 1" to 1.5". Make sure you leave a 1/4" gap between these planks to allow for water to drain. You will also need to use a Jig saw to cut a notch around the posts. By starting at the outer edge, usually the notch around the post will be done with the first two rows. Attach the planks with 3 exterior screws at each floor joist. When you get to the last row, you will need to rip the board down to the size needed to fit next the the house wall.

Please look the for the next post How to Build a Deck- (Rails) where we will discuss different types of handrail systems and how to install them!

Major thanks for the blog article.Much thanks again. Will read on...

ReplyDeleteComposite Deck Kansas City